This post looks at the Elmo E-80 projector which is a standard 8 model made by Elmo, a very reputable manufacturer, in Japan in the early 1950s.

My Elmo E-80 projector

I bought this Elmo E-80 projector from eBay as an addition to my small (but worryingly growing) collection of cine projectors. It was sold as a working unit, and it does power up and seems OK, but the two core mains lead supplied with it looks a bit dangerous, so I'm going to change that for a proper 3 core lead with earth before I use it properly.

The physical condition of the projector looks fine, with all the main elements of the projector basically working. The case needs a complete clean to remove 70 odd years of grime and the labels are a bit chipped and worn, but those are things that can be quite easily sorted.

Elmo E-80 Images

Elmo E-80 Description

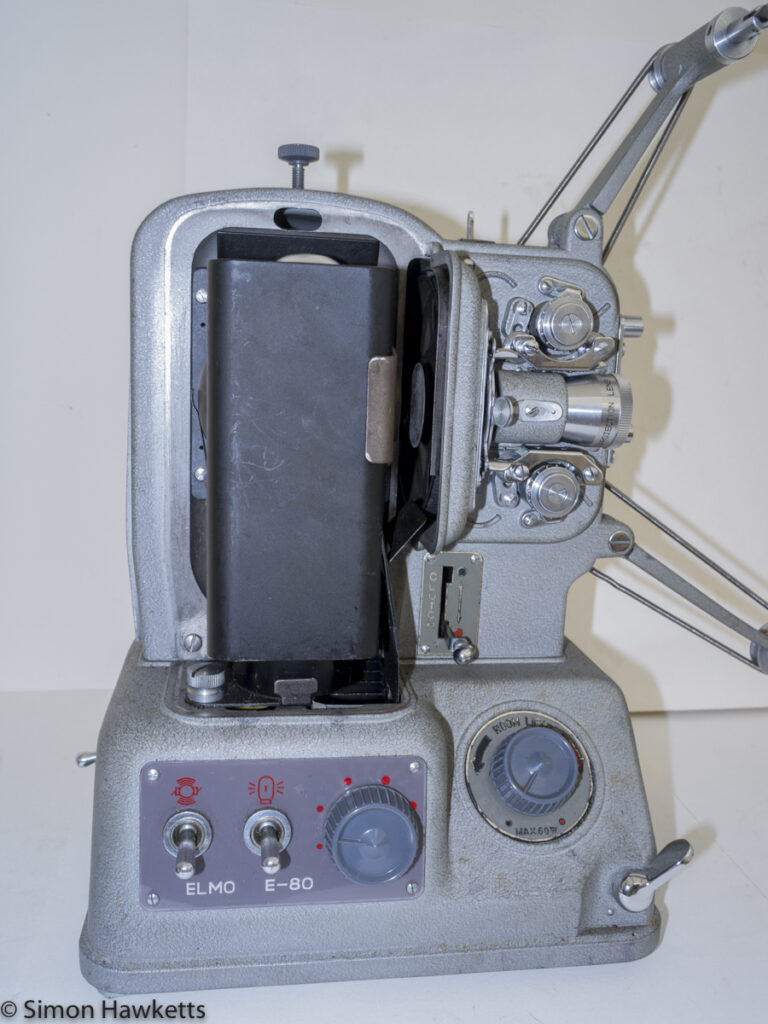

The Elmo E-80 looks a well build, solid projector with a well-thought-out set of controls to operate it. It shows Standard 8 mm film only, being manufactured some 15 years before the introduction of Super 8 film.

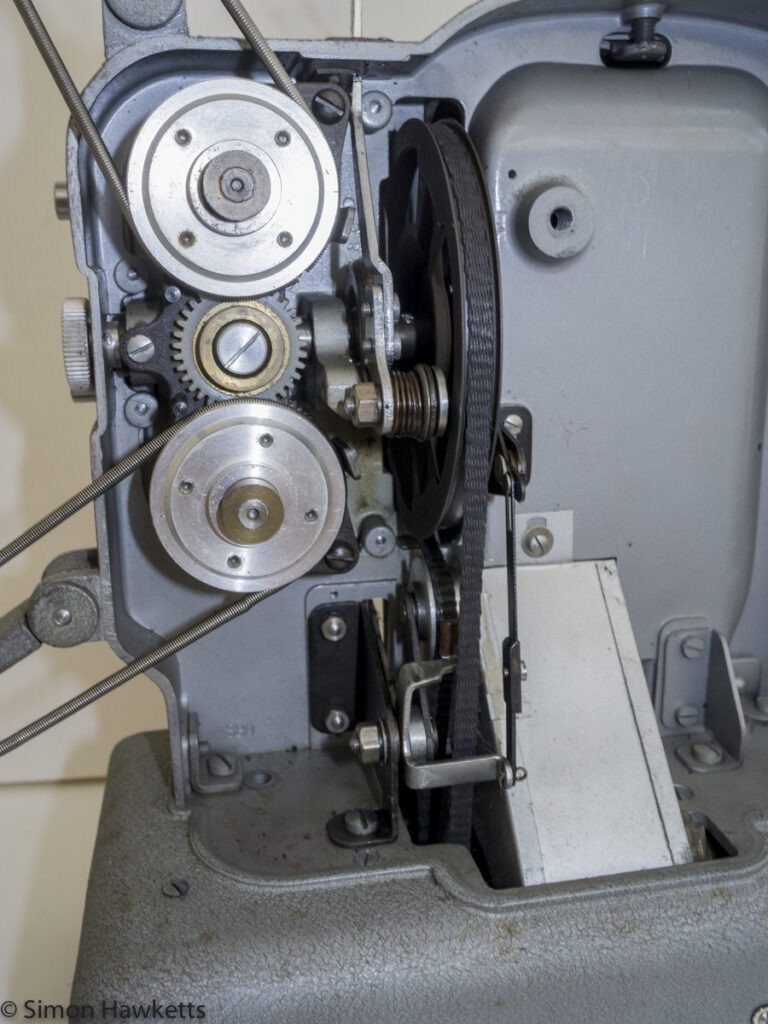

In common with many projectors of this era, the arms which take the film and take up reels fold out from the body of the projector to make it easier to pack into its carrying case. Once they are folded up into the working position, there are steel sprung drive bands which are attached to drive wheels on the back of each holder to drive the film.

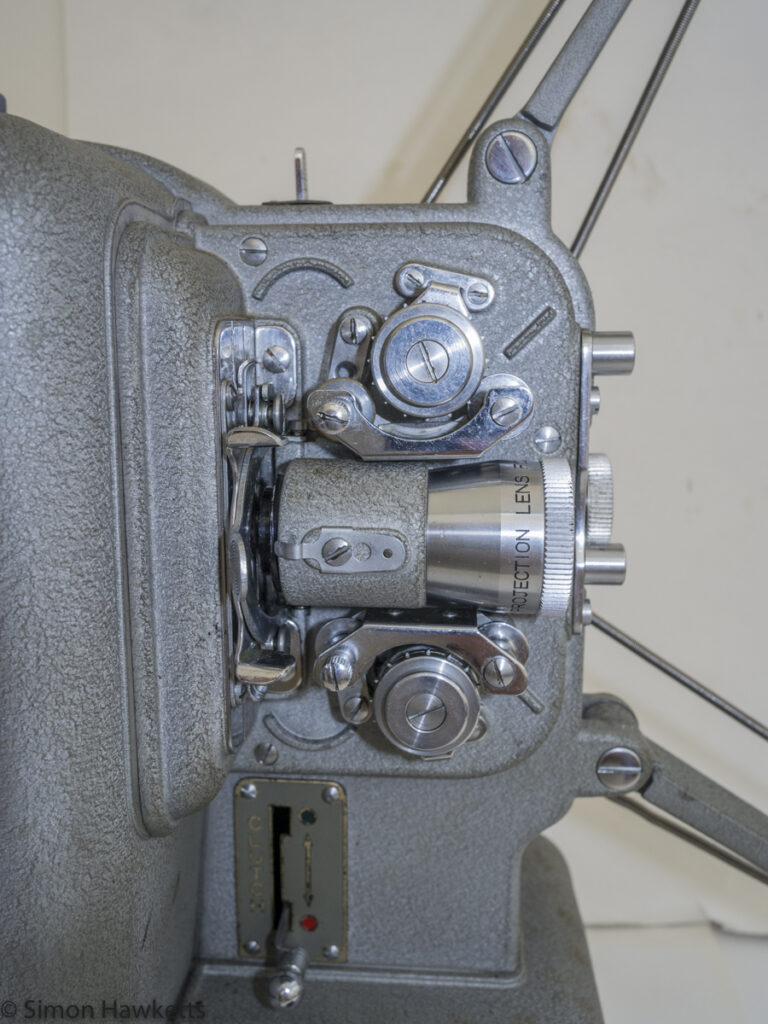

The film path is pretty obvious, with movable guides which are swung out of the way to thread the film and then pushed into place to force the film sprocket holes into contact with the film.

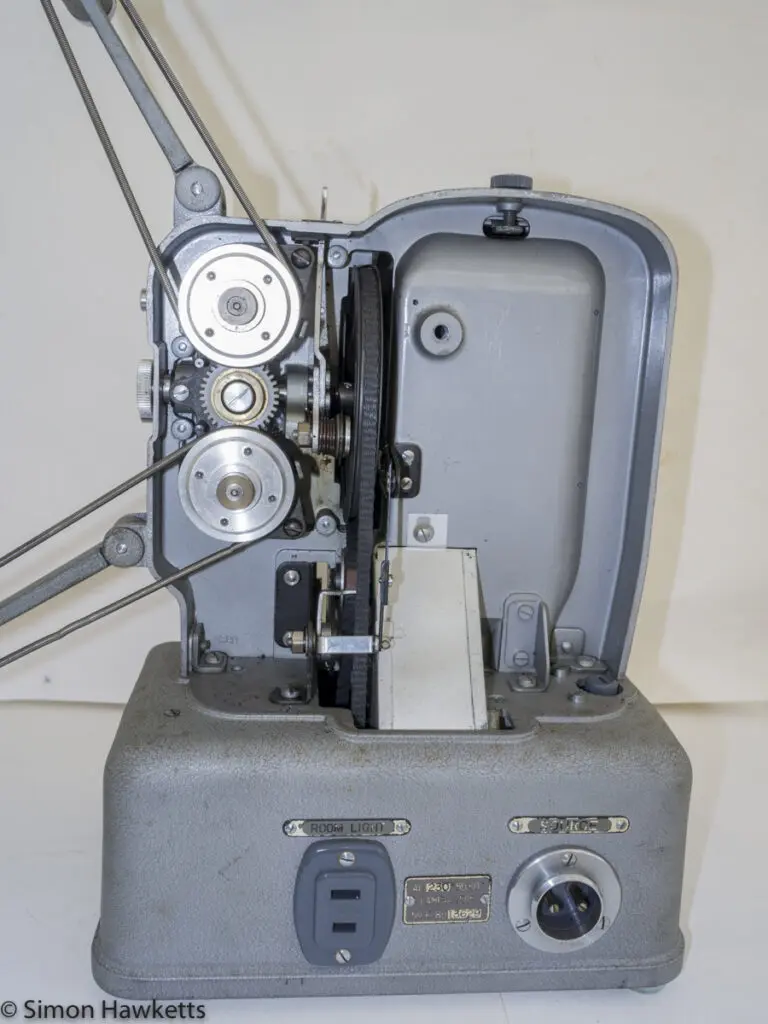

Once the film is threaded, the projector operation is really simple. There is a switch to turn on the motor, and another to turn on the lamp and on the same panel a rotary control to set the projection speed. Just under the main film path is a clutch which starts and stops the drive from the motor to the projection mechanism, and at the top of the projector is a lever which alters the framing. On the back of the projector is a switch which alters the direction of the motor, which is labelled (logically) 'Forward' and 'Reverse'.

There is one other rotary control on the side of the unit which is labelled 'Room Light' and this is used to control a light plugged into a socket on the reverse side of the projector via a two pin socket. This allows the projectionist to use a small table lamp as a local light, enabling him to see to thread the film etc.

Because the projector has a clutch which engages the motor to the shutter and sprocket driving system, it would be possible to have a situation where the film was loaded and not moving. To protect the film from burning in the situation the clutch engages a shield which blocks the light when the film is stationary.

For anyone who wants a projector to show old films the Elmo E-80 seems like a good unit to consider because it looks easy to work on with access via two removable panels to the drive unit and lamp.

Elmo E-80 Specifications

- Elmo E-80 standard 8mm projector

- Good quality unit made in the 1950s

- Individual Motor and Lamp switches

- Forward / Reverse switch

- Motor speed control

- Drive clutch with light filter

- Adjustable front foot for projector height

- Dimmable room light socket

- 750W Lamp

- 250v power

- Serial No: 13629

Uitvoerige beschrijving. Toch vraag ik mij af waar de twee schroefgaten voor zijn aan de voorzijde van de projector naast de tornknop. Ik ben geinteresseerd naar de functie hiervan.

M.v.g. Paul Oudendijk.