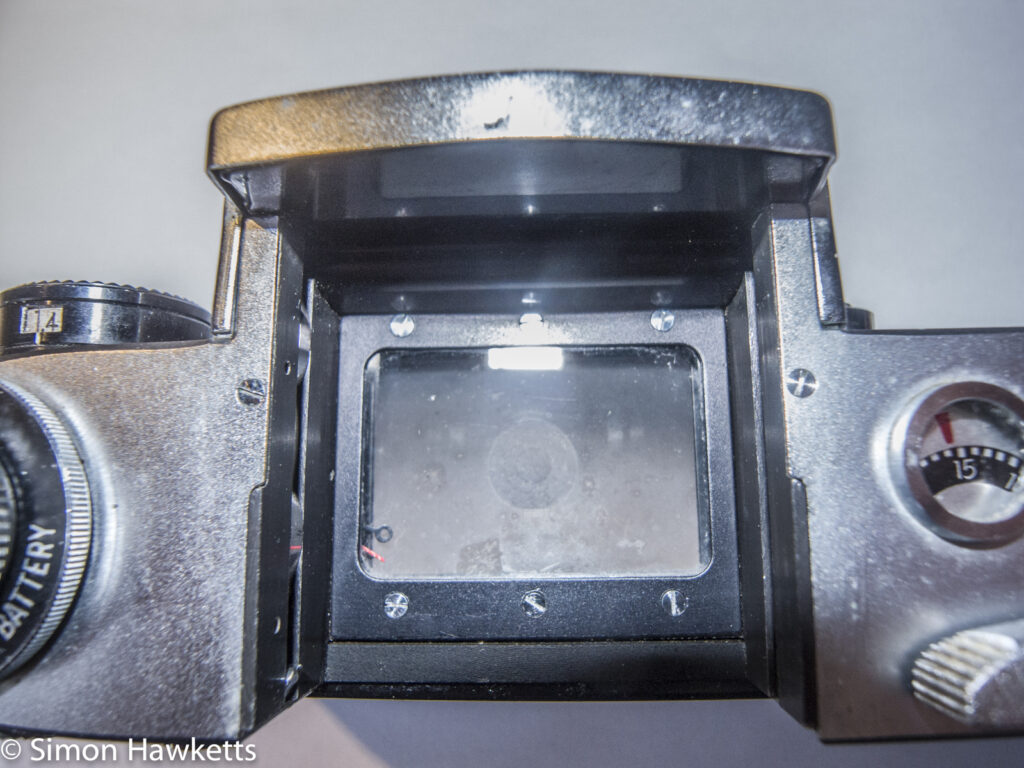

My recently acquired Miranda Sensorex has a few of issues which I need to put right, including re-greasing the lens and some general clean up and lubrication, but the first issue I wanted to address was the muck and dirt on the focusing screen. I wanted to look at this first because it was awful and made trying to focus a difficult task, so this post covers the process I used to clean the Miranda Sensorex Focus screen.

Miranda Sensorex Focus Screen cleaning photos

Miranda Sensorex focus screen cleaning process

I had already cleaned the screen on my Miranda Fv, although that was in a much cleaner condition to start with, so I had a reasonable idea what would be involved, but the Fv doesn't have a metering needle in the focusing screen, so I knew this would be more involved.

I'll apologise now for the quality of the pictures - I had to take them as I was doing the job and I used my Ricoh GXR / S10, which is great for holding with one hand and snapping but doesn't have great noise performance in low light.

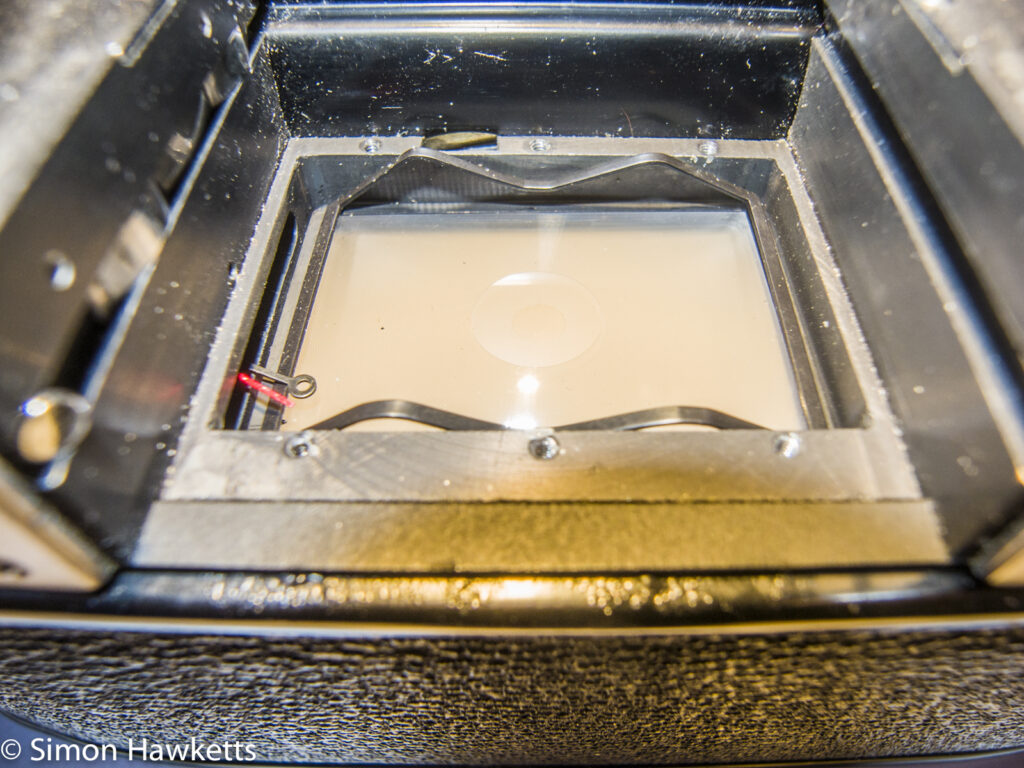

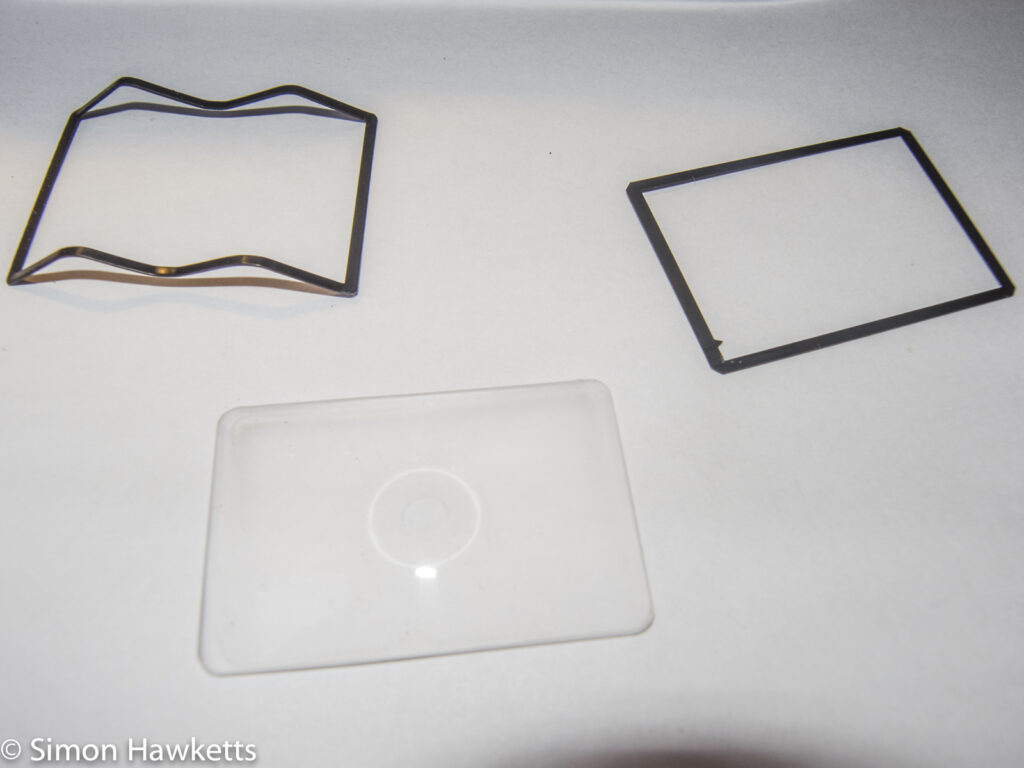

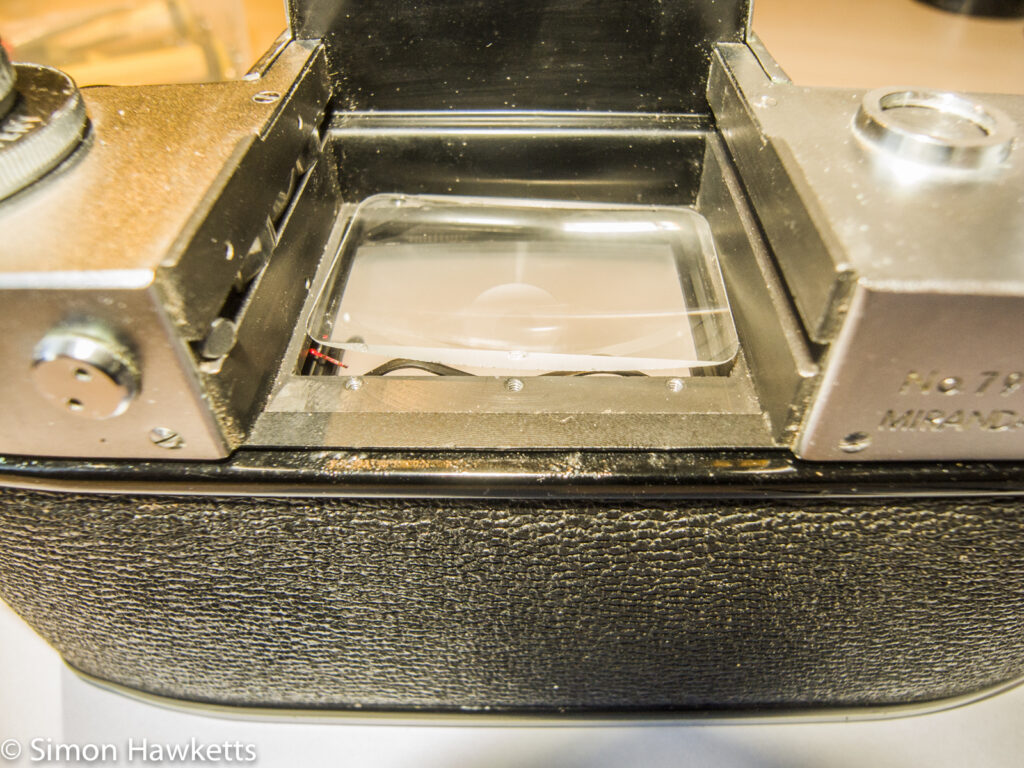

First, I loosened and removed the six screws which hold the retaining piece down. As these were undone, the piece pushes up because there is a W shaped spring sitting behind it to keep the top element away from the meter needle, so be careful not to let it spring up and send pieces flying.

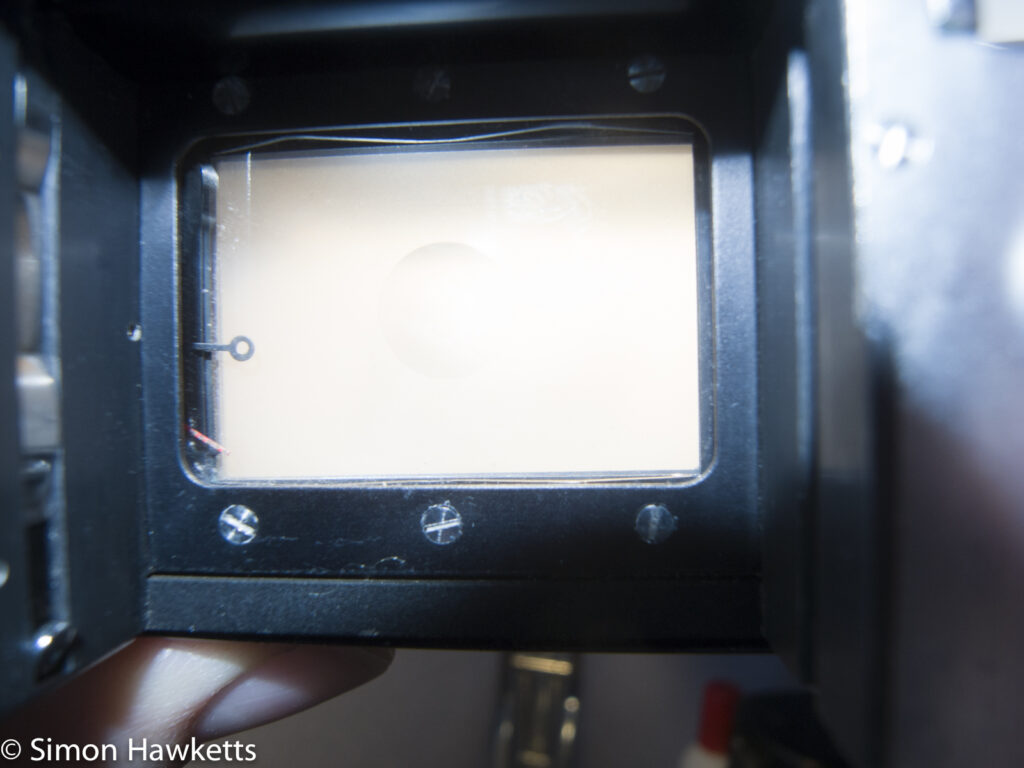

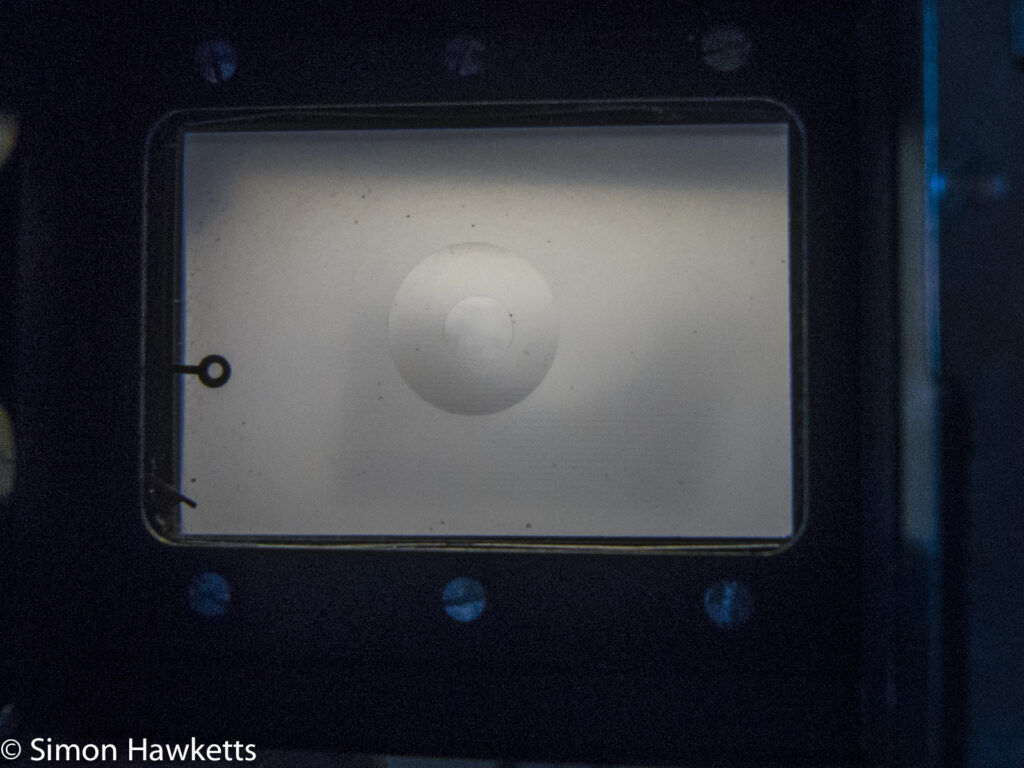

Once this was removed I thought I could see that the biggest problem in my particular case was the top curved condenser lens which had a large amount of muck and dirt on the underside.

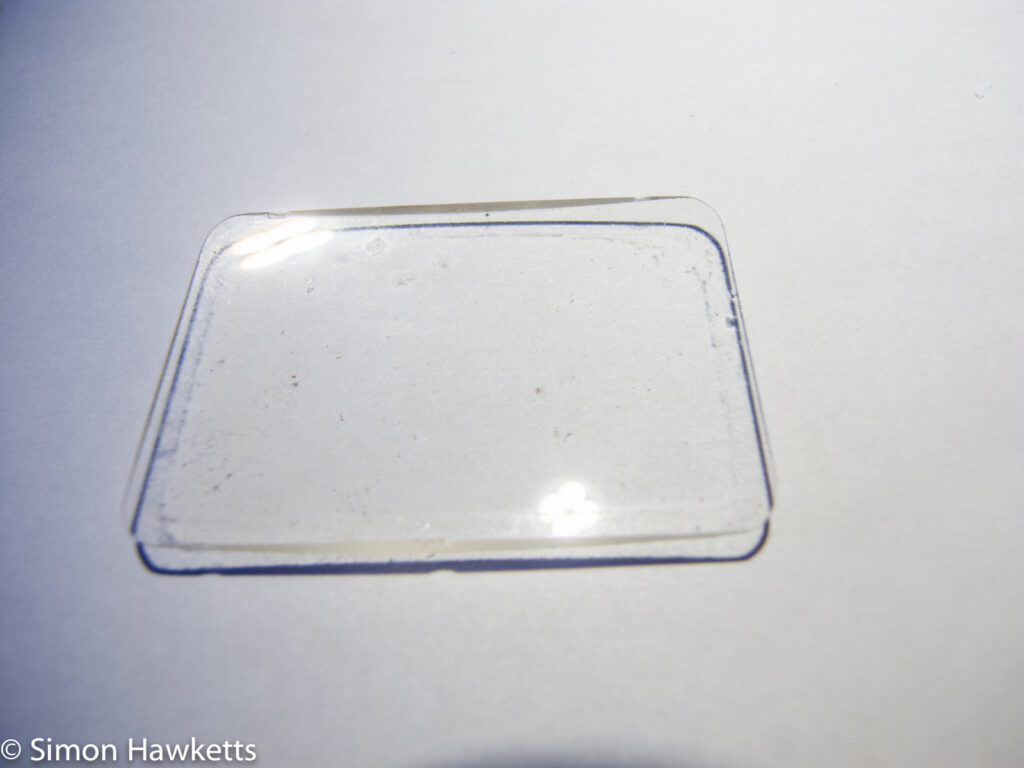

I carefully removed it with a pair of tweezers and decided to try to wash it first in soapy water. A word of caution here - the condenser lens is very delicate and looks like it could break with any excess force, so you need to be careful with it, in fact the example fitted to my Sensorex already has a small chip out of the top edge and I found that chip inside the focus screen assembly.

As with all disassembly jobs, you need to make sure you know the orientation of the condenser as it comes out. I found that the curvature was on the underside and I made sure all the time it was out of the camera I knew which side fitted towards the camera back.

I very carefully washed the condenser in warm water with just a small drop of liquid hand wash soap in my fingers and rinsed in it clean water. I then left it to air dry on a lens cleaning tissue. Although this seemed to remove the dirt, the glass still had a smeary look, so I had to do this again to try to remove everything.

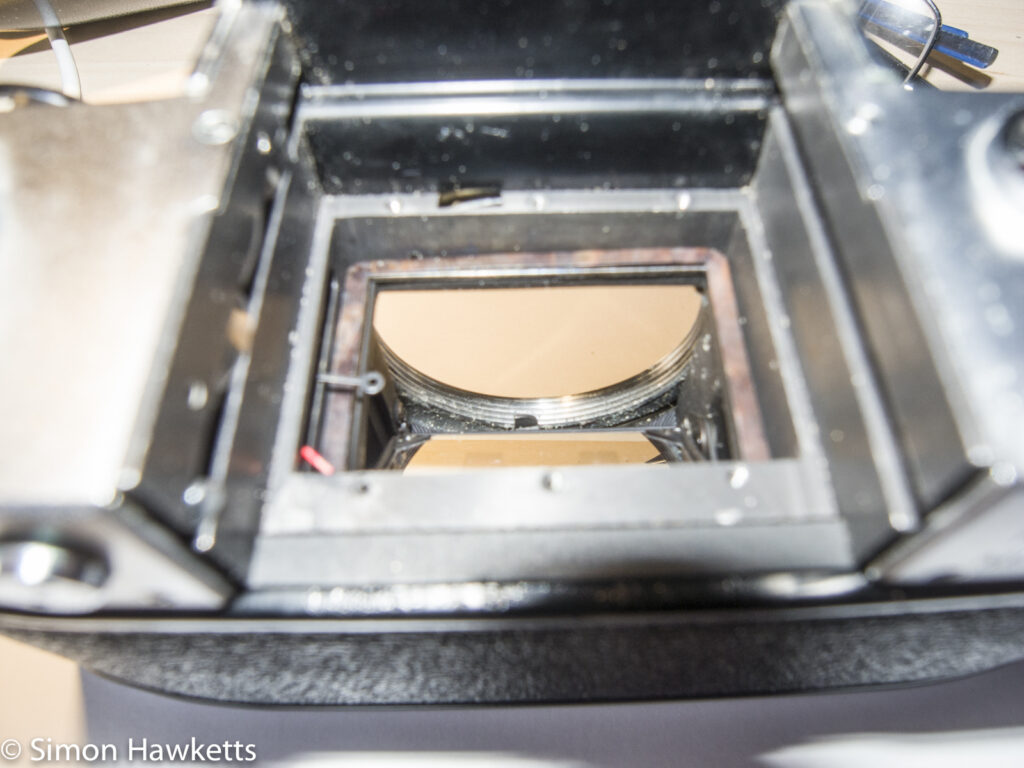

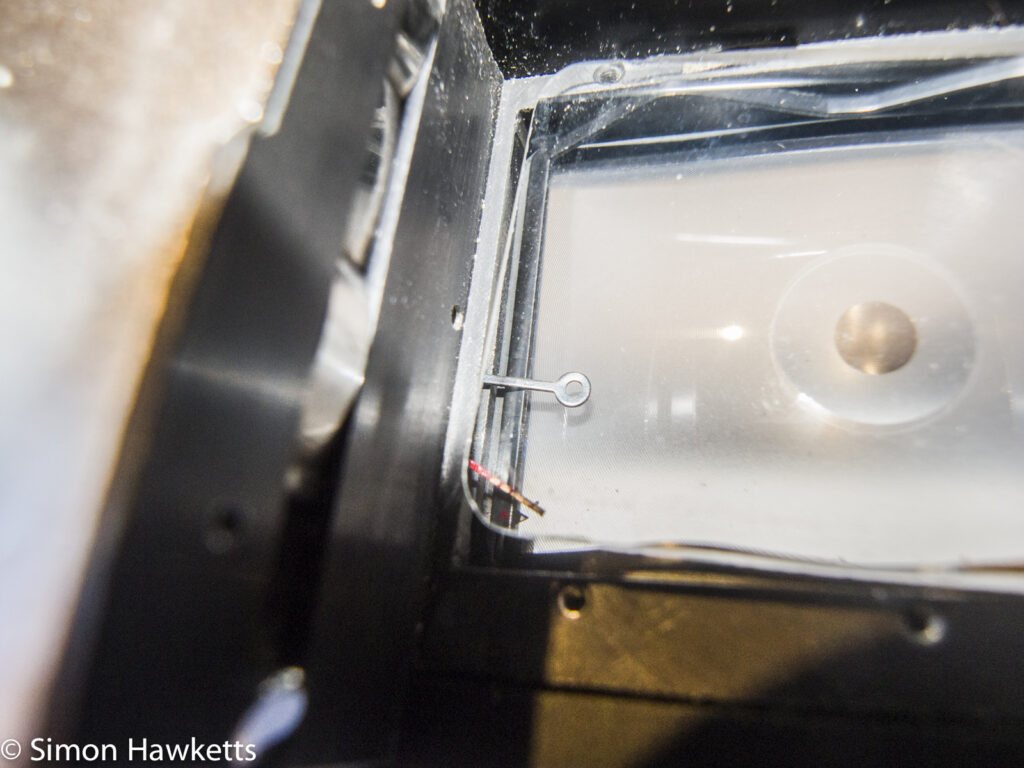

Next was a small shim around the edge of the focusing screen, followed by the focusing screen itself. I took both these out by pushing up on the side away from the meter needle from underneath using a cotton bud. Although there were also some shims under these, I left those in place because they didn't need to come out to get the focus screen clean. This is quite a difficult step because gravity will try to topple the focusing screen from the cotton bud, and it is a tight fit to get the screen out at an angle against the viewfinder wall.

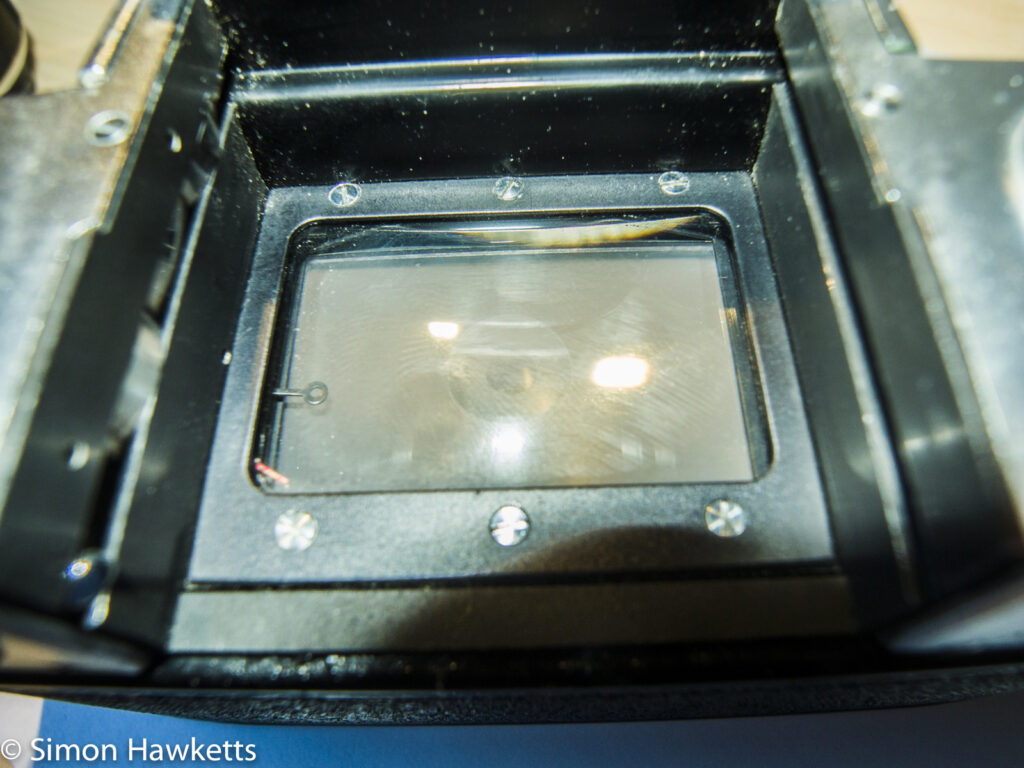

Once removed, I got most of the dirt off the focusing screen by careful use of a small clean lens brush and a blower, but I think it could probably do with a wash. I contemplated using my ultrasonic cleaner on it, but didn't like to try because I don't have a replacement - perhaps when I have a second body for spares I'll try that.

After I had cleaned the focusing screen (again making sure I knew which was the top and front) I refitted it and dropped the shim over the top, angling both of them in to fit under the meter needle. Then it was time to fit the condenser.

Putting the condenser back in place is a bit of a nightmare because you are trying to balance a curved lens on top of a w shaped spring. It doesn't easily sit in place and if you screw the holding plate down while it's off-centre the lens will crack. I also found a couple of times that it fell off the W spring and invariably fell on top of the meter needle!

I found that I had to put the components in place, hold the retaining plate in place and start the screws, and then gently press the condenser down and hold it while I did the screws up. As I moved it from side to side and up and down, it's possible to feel as it drops into the correct place. However, it's all quite nerve racking and having finally got everything correctly positioned and tightened down, I was dismayed to find that the match needle for the exposure system wasn't moving any more! I think I must have placed the W shaped spring over it rather than under it.

So it all came out again, and I had another try, this time also checking the aperture arm moved the match needle after I'd got the condenser positioned.

Once I'd done all this, the result is rather mixed. The image is definitely brighter and clearer, but there are still some dirt spots which all appear to be in the circles of the Fresnel screen focusing aid, so I'm sure I'm going to need to repeat the operation, but this time actually get the focusing screen wet and even possibly try using the ultrasonic cleaner on it.

This post is part of a series: The Miranda Sensorex

I really appreciate this article and wished I found this beforehand. I found a Miranda Sensorex that looked like it was barely used (not even scratched!), but the focus screen was very filled with dust and dirt (probably from sitting so many years). So I decided to open it up and clean it. Unfortunately after cleaning the focus screen, I rushed the process of trying to put it back together (forgot how everything went back together) and ended up cracking the condenser lens. So yes that condenser lens is very fragile. Good thing the Sensorex is a common Miranda camera model, so I was able to find another one very cheap. I will then take the condenser lens out of that one and try to put it together again more patiently. For those who own the Sensorex, I don't recommend doing this on your own.

Hi Cyrus - glad the article was a help to you.

Thank you for writing this article. Ive been wanting to clean the glass on a sensorex recently purchased. I didnt realize there were two bits of glass until reading about your process. Much appreciated.